All you need to know about tempering valves

Your hot water is not just there. How it gets to your tap is not smoke and mirrors, it is a carefully regulated and a precisely engineered solution to provide you with a controlled water temperature. A little-known valve that keeps you unscathed is the tempering valve.

What is a tempering valve?

A tempering valve mixes the hot water from the cylinder with cold water from the water main in a ratio which can be regulated by turning the temperature adjustment screw. There’s a small amount of variability to account for changes in the source temperature.

This should not be confused with a thermostatic mixing valve which can set a specific temperature on the valve.

Generally tempering valves are of brass construction, connected to water heater and cold supply with copper. Copper and its alloys are used because they are inherently antimicrobial, as an added safety component to the water supply.

Why do you need a tempering valve?

The temperature in a water storage heater should be stored above 60°C (140°F) to maintain a hot water supply clear of legionella bacteria. Water at this temperature has the potential to scald users easily, especially the young and the old.

It takes under a second of 70°C (158°F) water to scald a child or older person causing 3rd degree burns.

Generally, in childcare settings and elder care facilities, water supplied to sanitary fixtures such as basins, baths and showers is tempered (controlled) to less than 40°C (104°F) to ensure no scalding incidents. In these cases, generally a thermostatic mixing valve is used, which is more accurate and rapid to respond to temperature changes, but a tempering valve can be used.

How tempering valves work

Tempering valves are inherently simple in form and function. The valve contains two inlets and one outlet. The inlets are marked with H for hot and C for cold inlet connection. The final is labelled OUT, MIX or is labelled with an ↓ for the outlet.

RMC Heatguard tempering valve

Inside the tempering valve is a thermostatic element which is sensitive to changes in the water temperature. As the temperature changes the thermostatic element expands and contracts in concert. This movement controls a piston that selectively restricts the hot water and mixes in the cold water to achieve the predetermined temperature.

The tempering valve is accurate to approximately +/-3°C, therefore the hot water from your fixture may vary slightly in relation to the temperature you have set the valve to.

In contrast, a thermostatic mixing valve is typically accurate to within +/-1°C.

Where are tempering valves usually located?

The placement in the tempering valve changes depending on the brand. Some valve brands are allowed to be directly attached to the outlet of a water storage heater, such as the RMC brand. Other brands need to have a minimum of 1m (approximately 3’) of copper from the storage heater to the hot inlet.

Tempering valves may not be able to withstand town supply pressure, therefore the valve is located, more than likely, after a pressure limiting/pressure reduction valve.

Other valves that may be located in the valve train before the tempering valve, cold water expansion valve, non return valve, line strainer, isolation valve.

APEX: Position of tempering valve in mains pressure water storage set up.

Are tempering valves adjustable?

Tempering valves have a screw adjustment, so you can fine tune your required temperature. The temperature is adjustable in most valves between 30°C and 55°C (86°F - 130°F)

Signs your tempering valve is faulty

Inconsistent flow - volume of water coming though your outlet oscillates

Inconsistent temperature - water temperature oscillates or is consistently above or below prescribed temperature.

Strange noises - rumbling noises when using the hot tap

Failure of the temperature reducing capability of your tempering valve can lead to severe burns.

Time to be severely burned is as follows

70°C – 1 second - adult, 0.5 seconds - child

60°C – 5 seconds - adult, 1 second - child

55°C – 30 seconds - adult, 7 seconds - child

50°C – greater than 5 minutes for adults and children

Ensuring a regular maintenance schedule, by a qualified contractor, is the key adequately controlling the temperature of your hot water outlets

Maintenance

A tempering valve should last a minimum of 5 years, some brands purport 15 year service life. Maintenance is important to ensure optimum performance, especially in areas where water requires heavy treatment or the water is high in minerals. 6 to 12 monthly maintenance checks are the norm, depending on manufacturer’s instructions.

APEX - Tempering valve cross section

Maintenance should include, but not be limited to

Flushing hot and cold water lines to remove debris

Cleaning of line filters and strainers

Temperature accuracy check (+/- 3°C)

The maintenance schedule should include tests of surrounding valves also, this can loosen lime scale and other debris, so working down the chain of valves in order is the best option.

A reputable plumbing company should always be called to change/maintain this important safety valve.

Can you fix tempering valves?

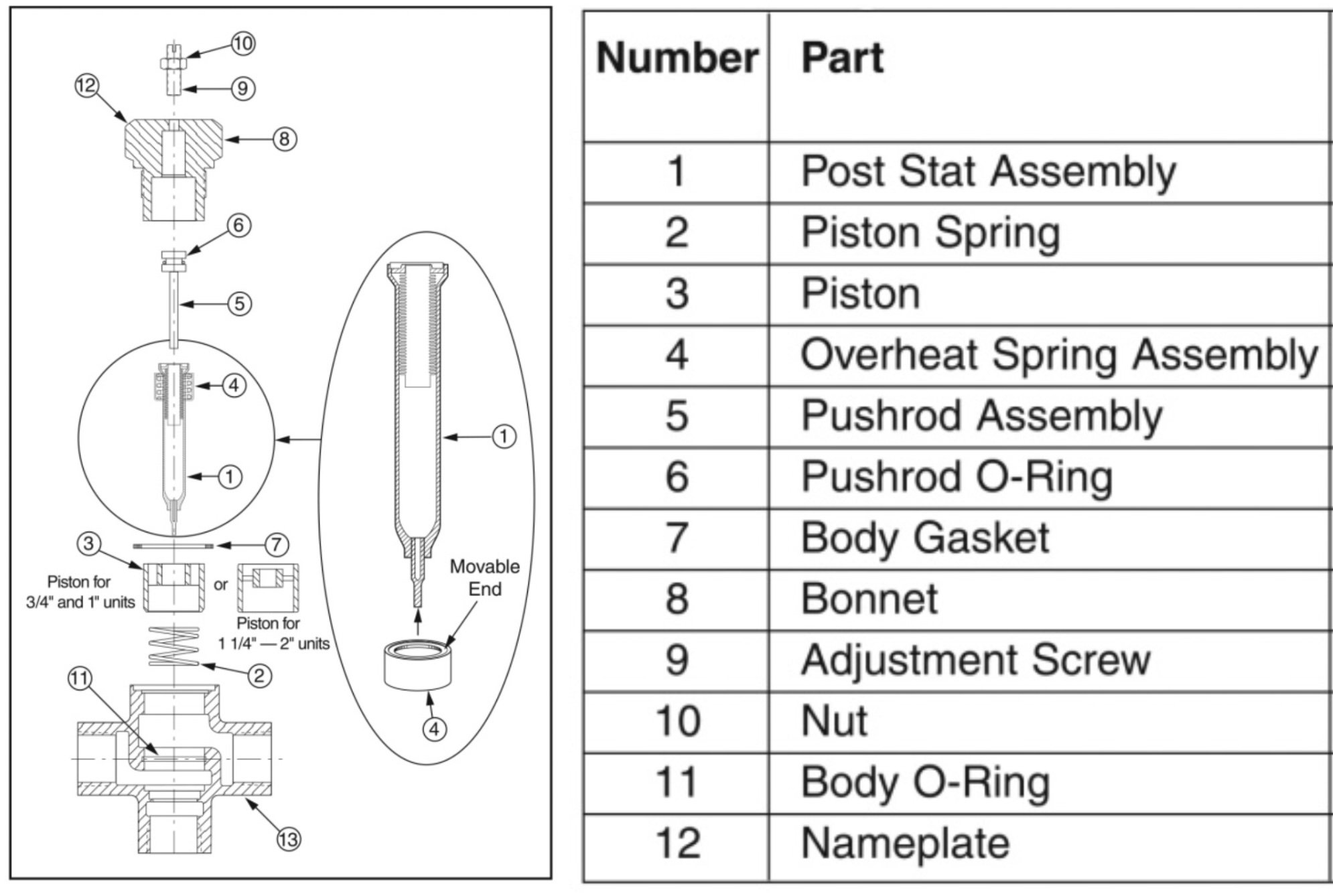

Some tempering valve manufacturers provide an option to fix your tempering valve.

Bell and Gosset valve parts list

Some valves are not fixable and you must replace the entire unit.

Brands of tempering valves

Calefi - Click here

Bell and Gosset - Click here

RMC - Click here

Apex/Watts - Click here

Nefa - Click here

Different valves for different uses

All tempering valves are not for all uses. Different specifications and types of valves are required for different systems, such as solar, industrial, circulating systems and domestic systems. Often the colour of the cap on the valve will tell you what systems the valve is designed for.

Orange Cap - heat pump (circulating) hot water systems and solar hot water systems.

Green Cap Tempering Valve - gas hot water systems.

Blue Cap Tempering Valve - electric water heaters.

Black Cap Tempering Valve - large capacity systems.

Sizes of tempering valves

For domestic use, tempering valves come in three standard sizes. 15mm (½”), 20mm (¾”) and 25mm (1”)

Larger commercial and industrial applications can use larger sized valves 65mm (2½”), or include a mixture of the smaller valves to service specific areas when branching from the main lines.

Caleffi Valve dimensions and inlet/outlet sizes

Standards tempering valves should comply with

AS 4032.2

NHS D08

BS 7942

EN 1111

EN 1287